Mold Business/ Special Purpose Machine Business/ CAD & CAM Data Business

Initially, KMI established pioneered the manufacture of only high quality blow plastic molds, over time, KMI is currently running six business pillars.

We aim to lead the industry in a wide range of service development in order to deliver accurate solutions to the plastic product industry.

Business01

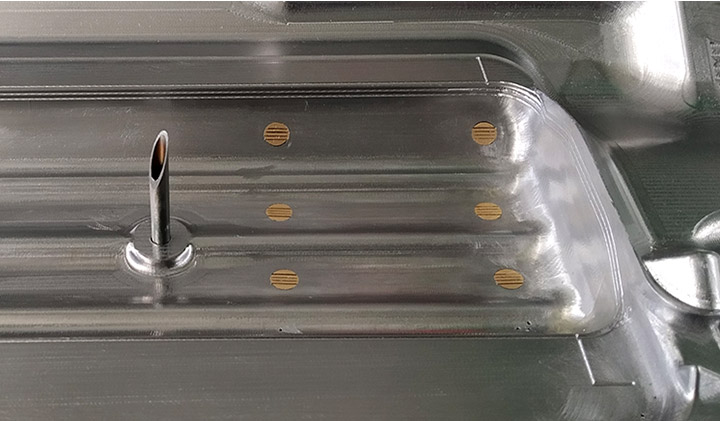

Blow Mold Business

Strength Points

Winning over 90% Indonesia Market Share in Automotive Blow Mold Business

Provides the same high quality as Japan.

We started business in 2004 by only doing blow mold maintenance. By considering the transportation cost will be higher if some repair or modification happened, then we decided to manufacture the mold in local. We started make new mold locally in2006 after some staffs returned from Japan who already been trained and acquire skills and ideas. Then our story began since here.

After 15 years, now we claim our position as Pioneer in Blow Mold especially in automotive fields. The market share of blow mold gradually increasing, and we achieved 90% as Top position in Indonesia. We are the only Japan company who produce automotive blow mold.

When procuring molds from overseas other than Japan, there is a tendency for quality to be inadequate compared to Japan, but our staff have mastered skills improvement and Japanese thinking in Japan, and are the same as in Japan. It is also attractive that the level mold is completed.

Business02

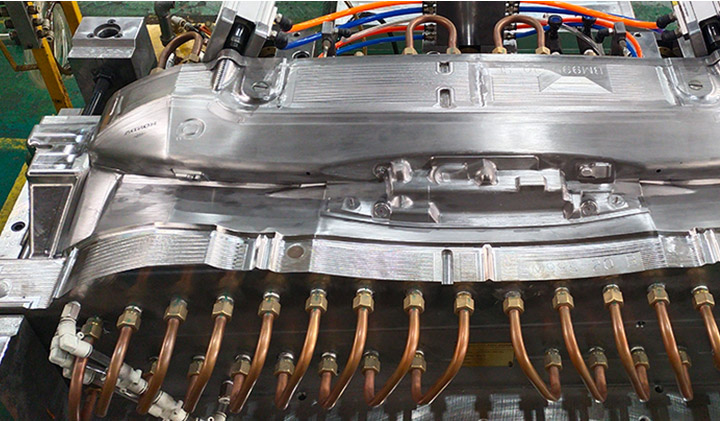

Injection Mold Business

Strength Points

we have capable to manufacture medium-sized 1,400t class injection dies.

Securing wide networks with local injection manufacturers.

We started the injection mold business when Nakamura Seiko joined the Kanto Seisakusho Group around 2013. Nakamura Seiko is mainly engaged in injection mold manufacturing. We have sent our staff to Nakamura Seiko to be trained injection mold technology. As a result, from around 2017, we have been able to manufacture injection dies with the same level of quality as in Japan.

As a Japanese injection mold manufacturers in Indonesia We are proud of able to manufacturing medium-sized 1,400t class injection dies . We also have many connections with Japanese, Korean, and local injection manufacturers in Indonesia, and we can respond to the detailed requests of our customers.

In the future, we are considering strengthening our equipment such as NC cutting machines, etc. in order to increase the production capacity of injection dies. We are confident that this will bring us closer to your needs."

Business03

Vacuum Forming Mold Business

Strength Points

Manufacture of large vacuum molds over 2200mm.

Now it has grown to provide molds to 5 countries.

Initially, no japanese mold maker in Indonesia that manufactures vacuum molds, but a refrigerator manufacturer wanted to make vacuum molds in Indonesia and was looking for a vacuum mold maker. At that time, we received a request to make a mold from our customer, which was only engaged in the blow mold business at that time. After that, I learned all the know-how of vacuum mold manufacturing from the manufacturer and absorbed it, and finally succeed to acquire the technology.

Since then, we have been strengthening our ability to provide vacuum molds for refrigerators to Panasonic's five countries: Brazil, Philippines, Vietnam, Indonesia, and India. Now, beside to refrigerators, we can handle cars, medical equipment, etc. regardless of the industry.

We are the only company in Indonesia who able to manufactures large vacuum molds, which handle up to 2200 mm or more. Both the bathtub type ""Female"" that has been used from the beginning and also Male Type which use mainstream compressed air . In addition to vacuum dies, we can also manufacture urethane foam jigs (cores) and trimming dies for deburring."

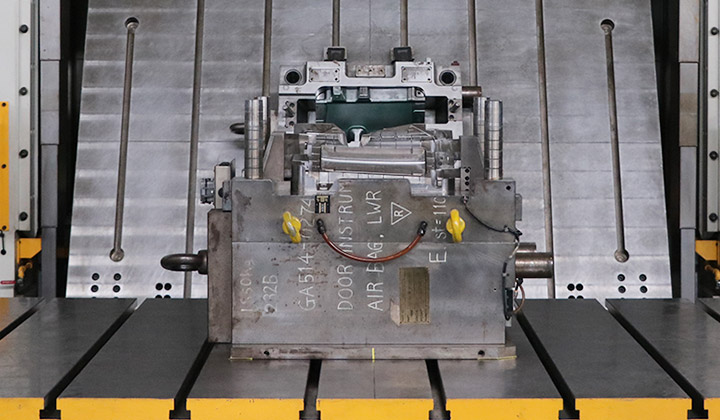

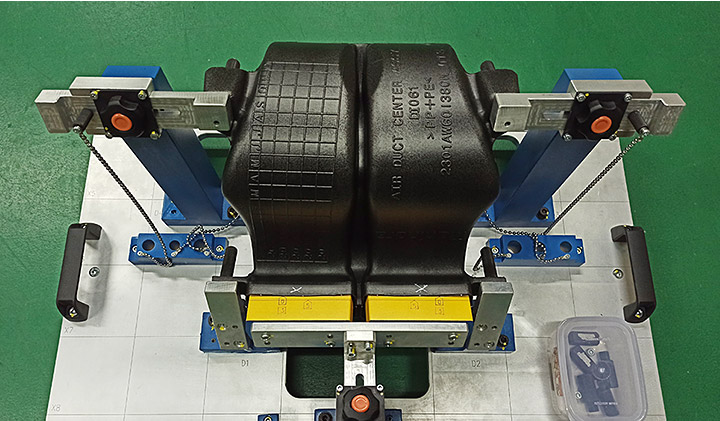

Business04

Special Purpose Machine Business

Strength Points

Manufactures Special Purpose machines with Japanese Level Safe

provide together with Blow Mold

The start of this business begins with the dispatch of our staff to Kanto Seisakusho so that we can build the finishing and processing machine business in Indonesia. Thanks to that, the staff has acquired Japan skills, and it has become possible to make processing machines with safety as Japan level in Indonesia as well.

In addition, we will be able to respond as flexibly as possible to customer's detailed requests such as delivery dates, or reduce labor costs in the production process. One of our major strengths is that we can handle processes that require post-processing and finishing, such as blow products, in combination with blow dies. The 3D data used from mold making, also used to finishing machines, so it is effective in reducing the number of meetings."

Business05

CAD / CAM Data Business

Strength Points

Own Licence to sales Intelectual Property

CAD / CAM Data with Japan quality can be sold.

CAD / CAM data is an intellectual property that can only be found on the screen. We are one of the few mold makers in Indonesia that owns an intellectual property right sales license that can sell such data. The CAD / CAM data sales business started around 2016, and sales are expected to be 8-9 million Japan Yen in 2021. Regarding CAD / CAM data, our design staff are trained in Japan so guarantee data quality as Japan level.

In addition, if requested from customer, we can send the data to Japan to be reviewed it by Japan experienced staff who have been working for 30 years. You will received the data at a same high quality or closer with Japan level.

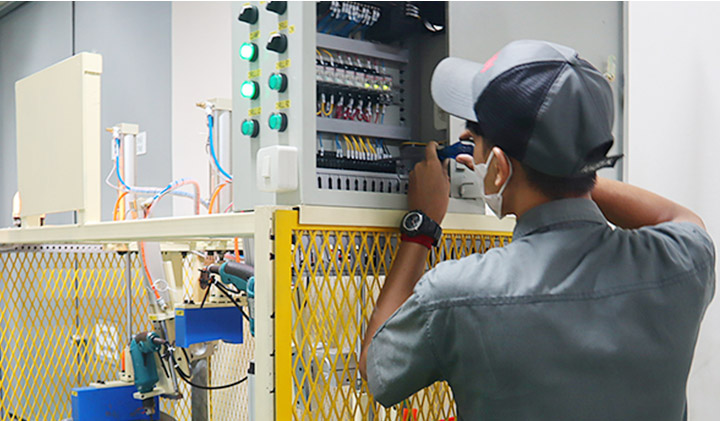

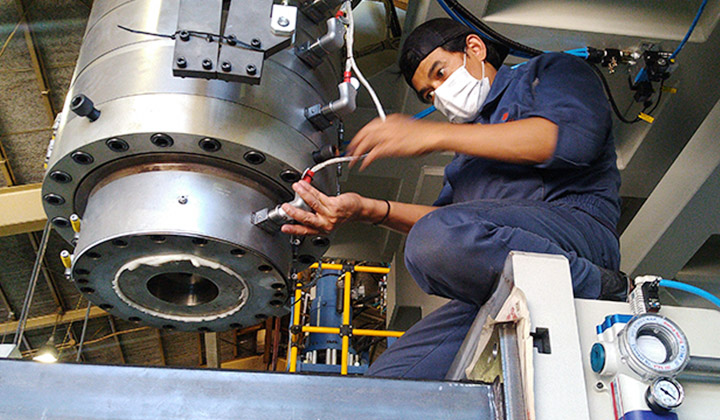

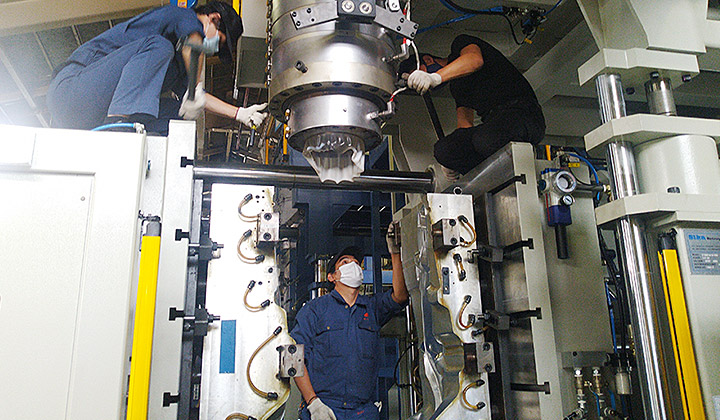

Business06

Blow Molding Machine Business

Strength Points

Consistent support from sales to installation of blow molding machines.

Fully support by staff who are familiar with molds.

We own a license to sell blow molding machines. In addition, since our staff has learned and mastered how to install, wire, and handle machines for about two years, we can provide a wide range of advice when initializing the installation of molding machines.

Our staff is familiar with the mold and has a good knowledge about the initial setting of the molding machine. we are not selling but also has skill to do setting of molding machine which can be entrusted. We can handle a wide variety of products, from small oil bottles to large machines that mold floats that float on lakes.

By merging with a blow molding die, it is a chance to introduce a blow molding machine that is smoother and more cost effective.

KMI's Strength

Own good relationship with Japanesse group company and staffs who gained "Japanese way of thinking"